Quality control has one of the highest priorities for us. Our management concept is aiming for perfection, therefore we a controlling every step within the production process starting from the quality control of the incoming unprocessed medical plants until the final quality control of the finished product in an independent German quality control laboratory.

After harvesting of the medicinal plants they will arrive securely packaged our production side were we check all documents accompanying the delivery and take samples for the incoming good quality control. During this first initial quality control step we are checking if the herbal material is fulfilling all requirements of the Chinese and European Pharmacopoeia. Only if the delivered material passes the identity check and fulfills the limits for contaminants (heavy metals, aflatoxins, pesticides and microbial contamination) the medicinal plants are released for the production of SFJDC. To ensure that each production batch of Shufeng Jiedu has always the same quality, efficacy and safety we only accept plants with the highest quality grade.

During the entire production process each step is carefully monitored in accordance to the Chinese and European GMP requirements and samples of the intermediated products are routinely taken for in process quality control analysis. After the production process is finished the products will be stored in an special quarantine warehouse and samples are taken for the final product quality control. One part of the samples is analysed in our own quality control department and the second part is send to a specialized German quality control lab. Only if both labs certify that the produced Shufeng jiedu Capsules fulfill all requirements of the Chinese and European Pharmacopoedia as well as the ISO 19609 standards the product is released from quarantine storage for sale.

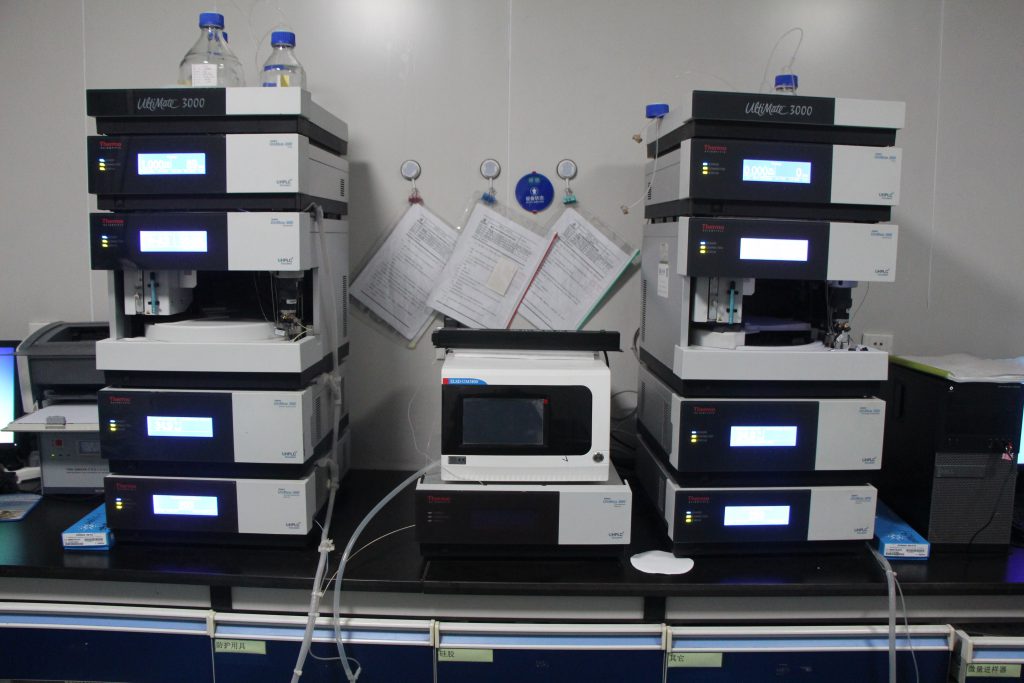

In 2020 we finished the construction of a new quality control and product development facility which has been equipped with only the best machines in order to be able to carry out our quality control always in line with the current state of science and technology, and to be able to constantly set new quality standards. Following the principle – The best is just good enough!